Topics in This Issue:

01:00 What types of circular economy services can lead to significant reductions in companies' argon purchases?

03:30 Two major recycling businesses help companies implement low-carbon and environmentally friendly approaches

01 What types of circular economy services can lead to significant reductions in companies' argon purchases?

Huanshi (Anchor):

Welcome everyone to Chip Unveiled. I'm your host, Huanshi. In this episode, we've invited a high-tech enterprise specializing in gas separation, purification, and environmental protection - Shanghai LifenGas Co., Ltd. (abbreviated as LifenGas). Now, I'd like to invite LifenGas business development director Liu Qiang to tell us about the company's background and main business activities.

Liu Qiang (Guest):

We're a relatively new company, and our main focus is on the circular economy. Our primary business is providing gas circulation equipment and services to our customers. The photovoltaic industry consumes large amounts of gas, and industry leaders such as LONGi, JinkoSolar, and JA Solar, Meiko are among our customers.

Huanshi (Anchor):

How should we understand the circular economy? What specific products do you provide?

Liu Qiang (Guest):

Our company's main business is argon recovery, which represents about 70%-80% of our current business volume. Argon makes up less than 1% of air composition and is used as a protective gas in photovoltaic crystal pulling. Traditionally, waste argon is discharged after use due to gas impurities. We identified this business opportunity in 2016 and collaborated with LonGi to develop the first argon recovery unit in China and globally, utilizing cryogenic processing. Since commissioning our first unit in 2017, we've installed dozens of argon recovery units in production facilities. LifenGas is a pioneer in argon recovery both domestically and globally, and our unit has been recognized as China's first set of argon recovery equipment.

Photovoltaic crystal pulling : It is a technology used to produce single crystal silicon, mainly achieved by the Czochralski method . The main process includes: charging and melting, vacuuming and filling with protective gas, seeding, necking and shouldering,diameter equalization and growth, wind-up, cooling and taking out the single crystal.

Argon gas recovery equipment site (Source: LifenGas official website )

Huanshi (Anchor):

Does LifenGas provide argon for this process or just handle the recycling?

Liu Qiang (Guest):

We focus solely on recycling, providing an on-site solution by setting up argon recovery units adjacent to monocrystalline silicon production plants. China's photovoltaic industry is highly competitive, with product prices are decreasing. LifenGas helps customers achieve substantial cost savings in monocrystalline silicon production.

Huanshi (Anchor):

In recent years, many companies in the supply chain must have been working hard to help monocrystalline silicon producers reduce costs. Otherwise, everyone would continue making losses and the industry would become unsustainable.

Liu Qiang (Guest):

In the crystal pulling process, our argon recycling alone can help customers reduce costs by 13-15%. A large crystal pulling plant previously consumed 300-400 tons of argon daily. We can now achieve a recovery rate of 90-95%. Consequently, factories only need to purchase 5-10% of their original argon requirement - reducing daily consumption from 300-400 tons to just 20-30 tons. This represents a significant cost reduction. We maintain our leadership position in the argon recovery industry with the highest market share both domestically and globally. We're currently developing projects both in China and internationally.

02 Two major recycling businesses help companies implement low-carbon and environmentally friendly approaches

Huanshi (Anchor):

Everyone hopes to see more technologies that can reduce procurement volume, as this is crucial for reducing carbon emissions..

Liu Qiang (Guest):

While argon recovery remains LifenGas's largest business segment, we're expanding into new areas. Our second focus is on several ongoing projects involving electronic specialty gases and wet electronic chemicals. The third area is hydrofluoric acid recovery for the battery sector. As you know, China's fluorite mines are non-renewable resources, and environmental regulations regarding fluoride ion emissions are becoming increasingly stringent. In many regions, fluoride ion emissions have constrained local economic development, and companies face intense pressure to meet environmental protection standards. We're helping customers re-purify hydrofluoric acid to meet electronic grade standards for reuse, which will become a crucial business segment for LifenGas in the future.

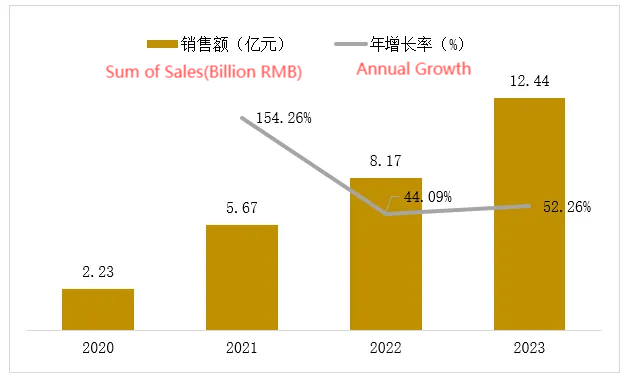

Silicon manufacturing based on recycling and purification technology in 2020-2023

High-purity argon market size and growth rate (data source: Shangpu Consulting )

Huanshi (Anchor):

After hearing about your business model, I believe LifenGas aligns perfectly with the country's carbon reduction strategy. Could you explain the technical process and logic behind the recycling?

Liu Qiang (Guest):

Taking argon recovery as an example, we use air separation principles to recover argon through cryogenic gas fractionation. However, the composition of waste argon gas varies significantly, and the crystal pulling process demands higher purity. Compared to conventional air separation, argon recovery requires more advanced technical and process capabilities. While the basic principle remains the same, achieving the required purity at a low-cost tests each company's capabilities. Though several other companies in the market offer argon recovery, it's challenging to achieve high recovery rates, low energy consumption, and reliable, stable products.

Huanshi (Anchor):

Does the battery hydrofluoric acid recovery that you just mentioned follow the same principle?

Liu Qiang (Guest):

While the overall principle is distillation, recovering hydrofluoric acid and argon in battery manufacturing involves very different processes, including material selection and processing methods, which differ significantly from air separation. It has required new investment and R&D efforts. LifenGas has spent several years on R&D, and we aim to launch our first commercial project either this year or next.

LifenGas Air Separation Unit (Source: LifenGas official website )

Huanshi (Anchor):

Beyond lithium batteries, hydrofluoric acid is widely used in the semiconductor field. It's a common industrial material, and recycling it presents a promising opportunity. How do you structure your pricing for users? Do you resell the recycled gas to customers, or do you use a different model? How do you share the cost savings with customers? What's the business logic?

Liu Qiang (Guest):

LifenGas offers various business models, including SOE, SOG, equipment leasing, and equipment sales. We charge either based on gas volume (per cubic meter), or monthly/annual equipment rental fees. Equipment sales are straightforward, especially in recent years when companies had sufficient funds and preferred direct purchases. However, we've found that production operation and maintenance requirements are quite demanding, including equipment reliability and operational expertise. Consequently, many companies now prefer to purchase gas rather than invest in equipment. This trend aligns with LifenGas's future development strategy.

Huanshi (Anchor):

I understand LifenGas was founded in 2015, yet you discovered this innovative field of argon recovery, effectively identifying an untapped and promising market. How did you discover this opportunity?

Liu Qiang (Guest):

Our team comprises key technical personnel from several world-renowned gas companies. The opportunity arose when LONGi set ambitious cost reduction targets and wanted to explore various technologies. We proposed developing the first argon recovery unit, which interested them. It took us two to three years to create the first unit. Now, argon recovery has become standard practice in photovoltaic crystal pulling globally. After all, which company wouldn't want to save over 10% in costs?

Chip reveals the truth of the anchor virtual reality (right) dialogue

Liu Qiang (left), Business Development Director of Shanghai LifenGas Co., Ltd.

Huanshi (Anchor):

You have promoted the progress of the industry. Today, photovoltaics is a very important category for earning foreign exchange overseas. I think LifenGas have made contributions in it, which makes us very proud. This industry upgrade brought about by technology and innovation is great . Finally, I would like to ask, since you are a guest at our Chip Reveal today, do you have any appeals or calls to the outside world ? We at Chip Reveal are very willing to provide such a communication platform.

Liu Qng (Guest):

As a startup, LifenGas's success in argon recovery has been market-validated, and we'll continue to advance in this area. Our other two key businesses - electronic specialty gases, wet electronic chemicals, and battery hydrofluoric acid recovery - represent our main development focus for the coming years. We hope to receive continued support from industry friends, experts, and customers, and we'll strive to maintain our standard of excellence, just as we've done with argon recovery, continuing to contribute to industry cost reduction and efficiency improvements.

Chip Secrets

Argon is a colorless, odorless, monatomic, inert rare gas commonly used as a protective gas in industrial production. In crystalline silicon heat treatment, high-purity argon prevents impurity contamination. Beyond crystalline silicon manufacturing, high-purity argon has wide applications, including the production of high-purity germanium crystals in the semiconductor industry.

The development of high-purity argon gas recycling and purification technology for crystalline silicon manufacturing closely correlates with photovoltaic industry growth. As China's photovoltaic technologies advance and silicon wafer production increases, demand for high-purity argon gas continues to rise. According to Shangpu Consulting data, the market size for high-purity argon gas in crystalline silicon manufacturing based on recycling and purification technology reached approximately 567 million yuan in 2021, 817 million yuan in 2022, and 1.244 billion yuan in 2023. Projections suggest the market will reach approximately 2.682 billion yuan by 2027, with a compound annual growth rate of approximately 21.2%.

Post time: Oct-25-2024