Oxygen Generator by Pressure Swing Adsorption (PSA)

• Small footprint, short construction time;

• Low investment and operating costs;

• Easy to start-up and stop;

• High degree of automation, fully automatic and unmanned operation;

• Operation at room temperature and low pressure with high safety and reliability;

• Simple process and easy to maintain;

• Oxygen purity of 90 to 94% (the rest is Ar + N2)

• Oxygen production is 4 - 100 Nm3/h.

|

Electric Steelmaking |

93% |

Blast Furnace Iron-making |

90% |

|

Welding Cutting |

94% |

Gold Melting |

93% |

|

Sewage Treatment |

90% |

Farming |

90% |

|

Glass Processing |

90%~94% |

Bronze Craft |

94% |

|

Lamps Production |

93% |

Kiln Combustion Aid |

90%~94% |

|

Chemical Fermentation |

90% |

Carbon Black Processing |

90% |

|

Chemical Fertilizer Industry |

93% |

Pharmaceutical Manufacturing |

90% |

|

Paper Manufacturing Industry |

90%~93% |

Waste Incineration |

90% |

|

Ozone Generation |

90%~95% |

Medical Care |

90%~94% |

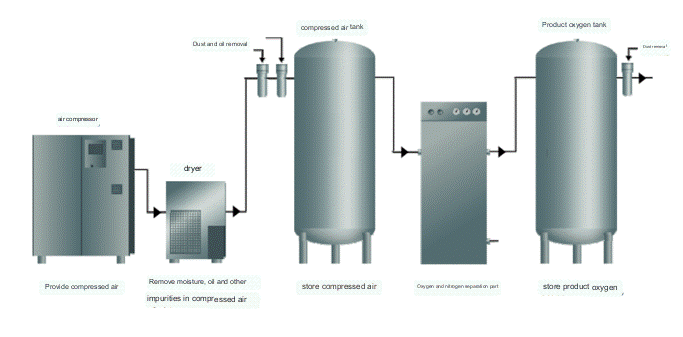

PSA oxygen production plants use ambient air as a raw material, which is safe and pollution-free. Atmospheric air is extracted, purified and dried, and pressurised adsorption and decompression desorption are carried out in the adsorber, and no harmful gases are produced.

PSA oxygen production equipment is composed of simple and non-toxic materials. The adsorbent used in the adsorption is a high quality zeolite molecular sieve, which is non-toxic and harmless, stable in nature, and has a certain sterilising effect, which can purify the air, and the oxygen produced by pressure swing adsorption can also be used as oxygen for breathing, escorting people's health.

The PSA oxygen concentrator is efficient for breathing, quiet and noiseless. Based on the principle of equilibrium adsorption of adsorption kinetics, the diffusion rate of nitrogen in the micropores of zeolite molecular sieve is much greater than that of oxygen, and the nitrogen is preferentially adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase and filtered by sterilization and dust removal for human respiration.

• Home use, home health care. Replace polluted air with clean, fresh, oxygen-rich air. Relaxes the brain and banishes fatigue.

• Rest at home. The elderly have a weakened respiratory system and immunity, and clean and sufficient oxygen is beneficial to the elderly.

• Medical oxygen. By providing oxygen to patients, it can be used to treat cardiovascular and cerebrovascular diseases, respiratory diseases, chronic obstructive pneumonia and other diseases, as well as severe hypoxic diseases such as gas poisoning.

• Healthy: Improves the oxygen concentration of the indoor environment, effectively alleviating altitude sickness, improving sleep quality and eliminating fatigue.

• Comfortable: Eliminates the need to wear multiple breathing masks or nasal oxygen tubes and alleviates various limitations of traditional oxygen inhalation.

• Fresh: It can adsorb traces of CO₂, CO, H2S and other harmful gases in the air and purify the air.

• Silent: Silent design, low noise and high efficiency to ensure a comfortable and quiet working environment.

• Safe: The oxygen process of the diffuse oxygen generator is a physical adsorption process, no chemical reaction, no pollution to the environment, green and environmental protection, and easy to use, safe and reliable, and low energy consumption.

• Modular, skid-mounted, quiet and efficient, ensuring a comfortable and quiet working environment and a wide range of application scenarios.

• Reliable performance: Imported microcomputer control, fully automatic operation, no special training of operators, just press the start button, it can operate automatically to achieve continuous production of oxygen/nitrogen.

• Low operating cost, nitrogen is produced in a few minutes after start-up, energy consumption is low, and nitrogen cost is lower than that of cryogenic air separation nitrogen production.

|

Unit Type Description |

LFPO-4A |

LFPO-6A |

LFPO-8A |

LFPO-14A |

LFPO-17A |

LFPO-20A |

LFPO-25A |

LFPO-35A |

|

Oxygen Production (Nm3/H) |

4 |

6 |

8 |

14 |

17 |

20 |

25 |

35 |

|

Oxygen Purity |

≥93% |

|||||||

|

Oxygen Pressure (Gauge Pressure) |

4.5-6.0Mpa |

|||||||

|

Start Time |

≤40 Min. |

|||||||

|

Public Engineering Consumption |

No cooling water, instrument air equipment. The device skid loading supply, the user site without installation |

|||||||

|

Degree of Automation |

Fully automatic and unmanned operation |

|||||||

|

Safety Performance |

Normal temperature and low pressure operation, high safety performance |

|||||||

|

Rated Power (kW) |

5.3 |

7.5 |

11.5 |

16 |

19.5 |

23 |

31 |

38.2 |

|

Floor Space (Length*Width*Height) m3 |

1.6×1.4×2.4 |

2.2×1.6×2.4 |

2.4×1.8×2.4 |

|||||

|

Unit Type Description |

LFPO-40A |

LFPO-52A |

LFPO-70A |

LFPO-76A |

LFPO-83A |

LFPO-120A |

LFPO-145A |

LFPO-190A |

LFPO-225A |

|

Oxygen Production (Nm3/H) |

40 |

52 |

70. |

76 |

83 |

120 |

145 |

190 |

225 |

|

Oxygen Purity |

93% |

||||||||

|

Oxygen Pressure(g) |

4.5-6.0Mpa |

||||||||

|

Start Time |

≤45 Min. |

||||||||

|

Public Engineering Consumption |

No cooling water, instrument air equipment. The device skid loading supply, the user site without installation |

||||||||

|

Degree of Automation |

Fully automatic and unmanned operation |

||||||||

|

Safety Performance |

Normal temperature and low pressure operation, high safety performance |

||||||||

|

Rated Power(kW) |

47.2 |

58 |

79 |

94 |

114 |

137.5 |

167 |

210 |

260 |

|

Floor Space (Length*Width*Height) m3 |

3.0×2.4×2.6 |

3.5×2.4×2.6 |

4.0×2.4×2.8 |

4.8×2.6×2.8 |

|||||