Argon Recovery Unit

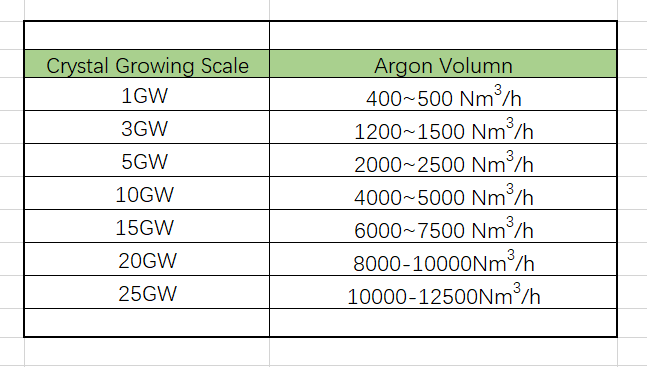

• Our argon recovery system is designed for various industries requiring argon separation and recovery, including photovoltaic crystal pulling, steel production, metallurgy, semiconductors, and new energy sectors. We've successfully implemented over 50 projects, with processing capacities ranging from 600 to 16,600 Nm³/h.

• The system processes waste argon through multiple stages: dust removal, compression, carbon removal, oxygen removal, and cryogenic distillation, resulting in high-purity argon. With an extraction rate exceeding 96%, we maintain product purity while achieving ultra-high recovery rates.

• For context, a 10GW crystal pulling plant typically consumes about 170 tonnes of argon per day. Our system can recycle over 90% of this, potentially saving customers around 150 million yuan, or over 20 million US dollars annually and significantly reducing gas production costs.

Proprietary Technology: Our independently designed and developed system holds intellectual property rights and has been optimized through years of market testing.

High Efficiency, Low Cost: We recover 96% of pure argon from waste argon at one-tenth the cost of purchasing new argon.

Optional Automatic Variable-load MPC Control: This technology adapts to changing requirements, coordinates with other control systems, and adjusts production load. It minimizes manual errors, reduces shutdown risks, saves energy, and maximizes production benefits.

Advanced Process Optimization: We use imported performance computing software to ensure optimal technical and economic performance.

Automatic Backup System: Our seamless backup system ensures stable argon supply, significantly reducing the risk of downstream production unit shutdowns.

Safety and Reliability: All components, including pressure vessels and pipelines, are of a high quality, and are designed, manufactured, and inspected in strict compliance with national regulations and with safety and reliability at the forefront.

Firstly, our company has a long-standing history and boasts a wealth of experienced technical experts who are well-versed in the design of gas separation and purification equipment. These professionals have mastered high-precision argon recovery technology, both domestically and internationally. Our team has significantly improved the argon recovery rate from an initial 80% to over 96% through technological advancements. This progress demonstrates our robust technical capability to meet and exceed our customers' project goals.

Secondly, our argon recovery system incorporates cryogenic distillation, which allows for greater by-product recovery compared to physical adsorption separation methods. This process provides customers with high-quality oxygen and nitrogen products, enhancing economic benefits. Customers can fully utilize these resources based on market conditions, potentially generating substantial additional economic value.

Thirdly, our independently developed integrated automatic variable load MPC (Model Predictive Control) technology is on par with those used by internationally renowned air separation companies. This advanced control system significantly reduces the risk of shutdowns and ensures long-term operation of the argon recovery system at peak efficiency, maximizing income.

Lastly, our company offers a fully integrated solution encompassing R&D, production, and technical services. Unlike simple intermediaries who may have natural price advantages, our comprehensive integration of equipment and technology results in significant time and cost savings, greatly benefiting project completion. We pride ourselves on our strong commitment to contractual obligations and service excellence. Beyond strictly adhering to technical agreement requirements, we ensure long-term effectiveness of after-sales products, offer preferential and reliable spare part arrangements, provide responsible and efficient technical services, and maintain a high standard of personnel training.

● l Huayao Argon Recovery Project-Cold Box&LAr Tank

● Gokin Argon Recovery Project-Cold Box & LAr Tanks

● JA Solar Item-Cold Box& Dual Diaphragm Gas Tank

● Meike Argon Recovery Project-Cold Box& LAr Tanks