Air Separation Unit(ASU)

-

Cryogenic Nitrogen Generator

Cryogenic nitrogen generator is equipment that uses air as a raw material to produce nitrogen through a series of processes: air filtration, compression, precooling, purification, cryogenic heat exchange, and fractionation. The generator’s specifications are customized according to users’ specific pressure and flow requirements for nitrogen products.

-

Liquid Air Separation Unit

The products of the all-liquid air separation unit can be one or more of liquid oxygen, liquid nitrogen and liquid argon, and its principle is as follows:

After purification, the air enters the cold box, and in the main heat exchanger, it exchanges heat with the reflux gas to reach a near liquefaction temperature and enters the lower column, where the air is preliminarily separated into nitrogen and oxygen-rich liquid air, the top nitrogen is condensed into liquid nitrogen in the condensing evaporator, and the liquid oxygen on the other side is evaporated. Part of the liquid nitrogen is used as the reflux liquid of the lower column, and part of it is supercooled, and after throttling, it is sent to the top of the upper column as the reflux liquid of the upper column, and the other part is recovered as a product. -

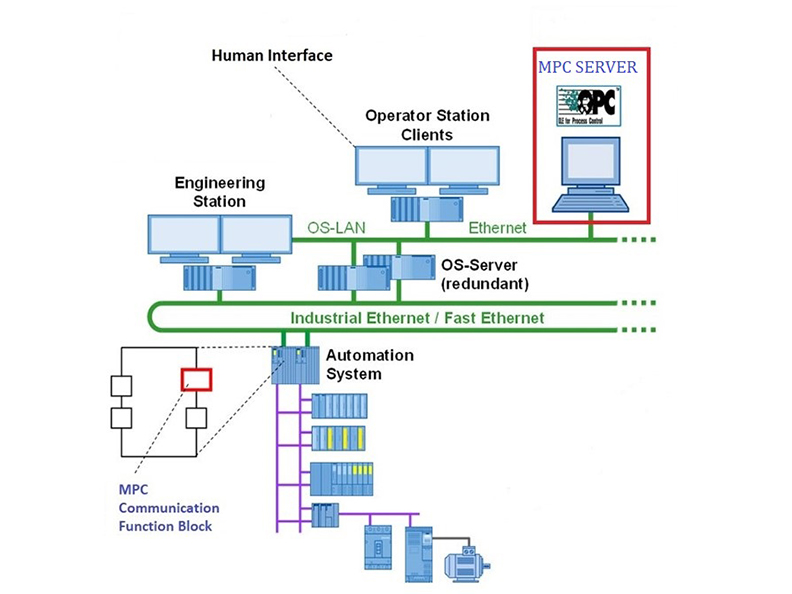

The MPC Automatic Control System of the Air Separation Unit

The MPC (Model Predictive Control) automatic control system for air separation units optimizes operations to achieve: one-key adjustment of load alignment, optimization of operating parameters for various working conditions, reduction of energy consumption during device operation, and decrease in operation frequency.

-

Air Seperation Unit(ASU)

An Air Separation Unit (ASU) is a device that uses air as feedstock, compressing and super-cooling it to cryogenic temperatures, before separating out oxygen, nitrogen, argon, or other liquid products from the liquid air through rectification. Depending on the user’s needs, the products of the ASU can either be singular (e.g., nitrogen) or multiple (e.g., nitrogen, oxygen, argon). The system can produce either liquid or gas products to meet different customer requirements.