The MPC Automatic Control System of the Air Separation Unit

Air separation units for metallurgical or chemical industries.

With the rapid development of large and ultra-large air separation units, gas production capacities are increasing. When customer demand changes, if the unit load cannot be adjusted promptly, it may result in significant product surplus or shortage. As a result, the industry's demand for automatic load change is increasing.

However, large-scale variable load processes in air separation plants (especially for argon production) face challenges such as complex processes, severe coupling, hysteresis and non-linearity. Manual operation of variable loads often results in difficulties in stabilizing working conditions, large component variations and slow variable load speeds. As more and more users require variable load control, Shanghai LifenGas was prompted to research and develop automatic variable load control technology.

● Mature and reliable technology applied to numerous large-scale air separation units, including external and internal compression processes.

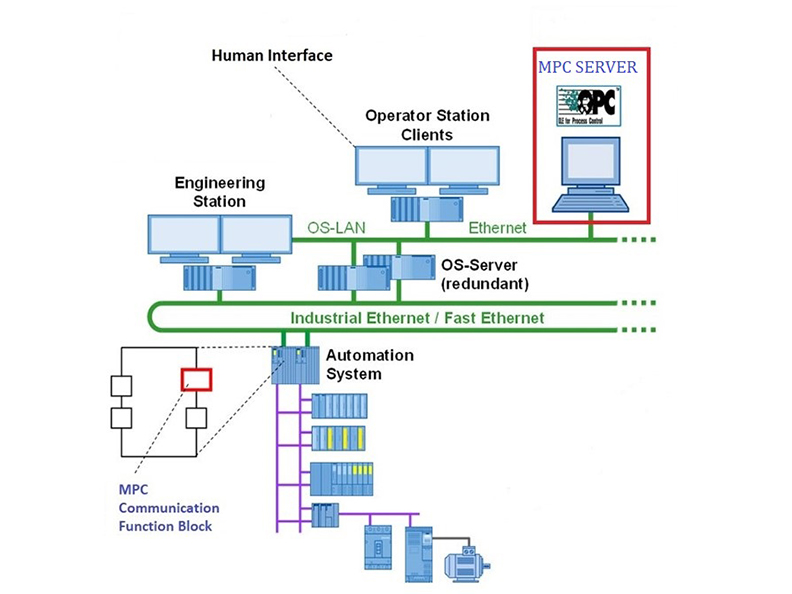

● Deep integration of air separation process technology with model prediction and control technology, delivering outstanding results.

● Targeted optimisation for each unit and section.

● Our world-class team of air separation process experts can propose targeted optimization measures based on the specific characteristics of each air separation unit, effectively reducing energy consumption.

● Our MPC automatic control technology is specifically designed to maximise process optimization and automation, resulting in reduced manpower requirements and significantly improved plant automation levels.

● In actual operation, our in-house developed automatic variable load control system has achieved its expected objectives, providing fully automatic load tracking and adjustment. It offers a variable load range of 75%-105% and a variable load rate of 0.5%/min, resulting in a 3% energy saving for the air separation unit, far exceeding customer expectations.